- Home

- Branson Ultrasonic Cleaners

- 1/2 gallon & under

Branson Ultrasonic Cleaners

Branson 1800 Cleaner

From $557.00

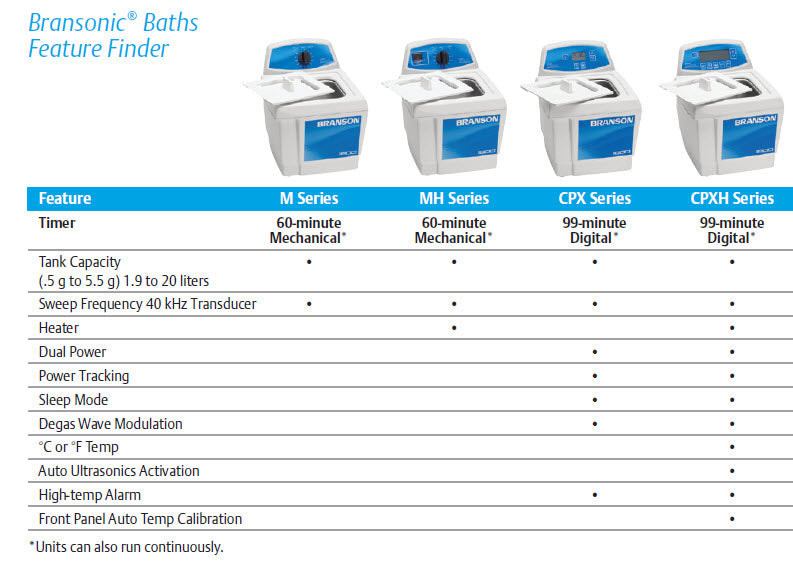

Branson Ultrasonics has long been recognized as a leader in Ultrasonic Cleaner development, pioneering to use of rugged, powerful 40 kilohertz piezoelectric transducers and sweep frequency. Bransonic baths are used in R&D Laboratories, dental labs, surgical centers, and in a wide variety of light Industrial cleaning applications.

Medical and dental labs: Branson offers safe and consistent cleaning of dental and surgical instruments. Units can also sterilize with the use of appropriate cleaning solutions.

Industrial ultrasonics: Removal of soils, rust, oil, and drawing compounds from machine parts in production. Ultrasonic cleaners are also widely used to return repaired or serviced components to their original pristine condition.

Electronics: Easily remove flux and other soils from circuit boards, quartz crystals, individual electronic components, iPhone and iPad circuit boards, computer parts and more.

Jewelry: Restore the sparkle to watches, bracelets, necklaces, rings, and loose gemstones.

Laboratory: Cleaning glassware, lenses, ceramic, metal components, and instruments.

Branson CPX units feature their elevated control panel - well out of the splash zone, and positioned for easy access during cleaning. Your workers' hands are always above the liquid, increasing safety.

All Bransonic machines have ultrasonic sweep frequency technology to eliminate standing waves, and rugged 40 kHz industrial transducers.

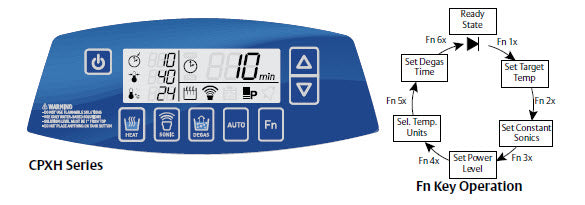

The CPX and CPXH Series units are identical in operation, except that the CPXH units have heating capabilities. Unheated units are normally used in sample preparation, or in applications involving temperature sensitive parts or solutions.

Other CPX Series advanced features:

The CPX Series units features extended degassing capabilities (up to 99 minutes). This allows for multiple non-cleaning applications like:

Branson M & MH units feature their elevated control panel - well out of the splash zone, and positioned for easy access during cleaning. Your workers' hands are always above the liquid, increasing safety.

Branson M & MH units feature their elevated control panel - well out of the splash zone, and positioned for easy access during cleaning. Your workers' hands are always above the liquid, increasing safety.

All Bransonic machines have ultrasonic sweep frequency technology to eliminate standing waves, and rugged 40 kHz industrial transducers.

The M and MH Series units are identical in operation, except that the MH units have heating capabilities. Unheated units are normally used in sample preparation, or in applications involving temperature sensitive parts or solutions.

M Series - The Value leader for dependability and cost effectiveness

The Bransonic M Series includes two easy-to-use models in five sizes: the M and MH Series. Both models are designed to give your operators a zero leaning curve, with set-it-and-forget-it 60 minute mechanical timers, which can also run continuously. MH Series units add heating.

Features:

The Branson Quick Start Guide will get you up and running quickly with your new Bransonic Ultrasonic Bath.

Do this:

For models 3800, 5800, and 8800:

For all Models:

NOTE: To stop ultrasonics at any time, press the Sonics key ( ).

Degassing

NOTE: To stop degassing at any time, press the Degas key ( ).

Activating Heat (CPXH Only)

NOTE: To stop heating at any time, press the Heat key ( ).

NOTE: Heat can be activated before or during ultrasonics.

This video will walk you through the cutting edge features of Branson's CPX Series cleaners.

| Specification |

Model 1800

|

Model 2800

|

Model 3800

|

Model 5800

|

Model 8800

|

| Overall Size | 10"l x 12"w x 11.5"d | 13.5"l x 12"w x 11.5"d | 16"l x 12"w x 14.5"d | 16"l x 15.5"w x 14.5"d | 24"l x 18"w x 14.5"d |

| Tank Size | 6"l x 5.5"w x 4"d | 9.5"l x 5.5"w x 4"d | 11.5"l x 6"w x 6"d | 11.5"l x 9.5"w x 6"d | 19.5"l x 11.5"w x 6"d |

| Weight | 10 lbs | 12 lbs | 17 lbs | 21 lbs | 40 lbs |

| Frequency | 40 kHz | 40 kHz | 40 kHz | 40 kHz | 40 kHz |